Reusable Wastes

Waelz Kiln

High-Temperature Smelting · The Core Process of Resource Recycling

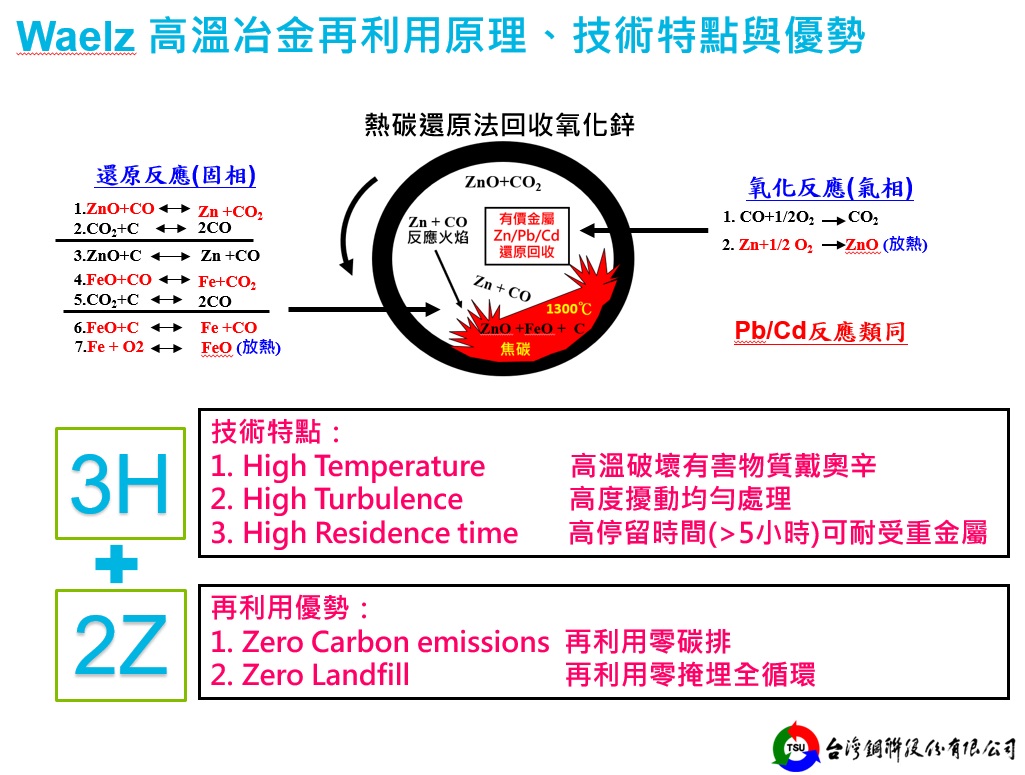

Electric Arc Furnace fly ash dust resource recovery process mainly utilize rotary Kiln high temperature smelting technology for processing fly ash dust and recover Crude Zinc Oxide. Considering the properties and characteristics of Electric Arc Furnace fly ash dust and widely adopted treatment technology internally, TSU invested and imported high temperature smelting (Waelz Kiln) process from Germany to treat the fly ash dust (EAF Dust) generated from Electric Arc Furnace Steel Mills. TSU owns and operates two Waelz Kilns with total capacity of 198,900 tons annually.

The Waelz Kiln Process technology used by TSU has decades of proven applications history in Europe, US, and Japan and is commercially mature and stable technology. Pelletized Basic SRP (Self Reducing Pellets) EAF Dust along with Coke, slag forming agents (such as used refractory, heavy metal and oil contaminated soil, Zinc containing organic sludge, lime, hydrated lime, incinerator fly ash etc.) are mixed and fed via belt conveyors into Waelz Kilns (Kiln No. 1: 3.6 m O.D. x 40 m long; Kiln No. 2: 3.6m O.D. x 50 m long) under 1,300℃ high temperature environment to undergo 5 to 6 hours reduction and re-oxidization smelting reactions. Not only valuable metal resources can be recovered from EAF Dust, EAF Dust hazardous industrial waste is also converted into stable and harmless completely reusable rotary kiln slag.

High-Temperature Smelting Waelz Kiln Process

199,000 tons

Annual Processing Capacity of Two Rotary Kilns

3.6 meters

High-Efficiency Kiln Diameter Specifications

1300 °C

High-Temperature Thermal Energy Achieves Resource Transformation

5–6 hours

From Dust to Recycled Resources

About

Service

NEWS

Investors

Reports

Contact Us